Adding a Digital Scooter Speedometer and trip meter

Most scooters have fairly basic instrumentation. My 150cc Chinese scooter has a speedometer, oddometer, tachometer and a fuel gauge. The value of a tachometer on an automatic scooter is questionable since there's no gear changing and no way to "over rev" the engine, still, it can be useful for setting the idle speed.

The speedometer is useful of course, but it's not accurate. Mine reads about 15% high most of the time, so at an indicated 65mph the true speed is closer to 55mph. The oddometer is about 4% optimistic, recording 100 miles for each 96 miles ridden.

There is a way to add to the instrumentation at low cost though. For under $30 you can add an accurate digital speedometer, oddometer, trip mileage meter, clock, trip timer, average speed indicator and maximum speed recorder. All you have to do is add a "bicycle computer"!

There is a way to add to the instrumentation at low cost though. For under $30 you can add an accurate digital speedometer, oddometer, trip mileage meter, clock, trip timer, average speed indicator and maximum speed recorder. All you have to do is add a "bicycle computer"!

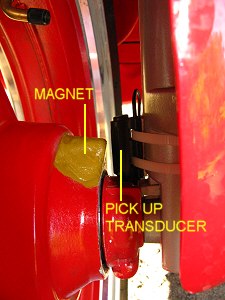

A bicycle computer simply records the number of times the wheel revolves and calculates everything from that. Most operate by attaching a magnet to the wheel and placing a small pick up transducer on the front fork. Each time the magnet passes the transducer it induces a small voltage when the magnetic field crosses a coil of wire in the transducer. The "computer" records this voltage pulse and uses it to calculate and display the speed and distance functions. Just about all bicycle computers can be adjusted for wheel size. You input the circumference of the wheel (distance travel led each time the wheel revolves) and the computer does the rest.

Of course bicycle computers are designed to be mounted on bicycles, not scooters. The magnet is designed to attach to the spokes of a bicycle wheel, so you have to use some ingenuity to attach it to a scooter wheel. Similarly the pick up transducer is designed to be mounted on one arm of the front fork of the bicycle and it has to be positioned so that the gap between it and the magnet is no more than 1 or 2 mm. Again some ingenuity may be required to attach it to the scooter fork and get the gap small enough for the unit to operate.

The image on the left shows how I attached the magnet to the wheel. I scraped the paint off the wheel and attached the magnet in place using epoxy putty. By placing the magnet close to the hub you can minimize any effect on wheel balance and the centrifugal force on the magnet is minimized. How long it will stay attached I don't know. However if it does come off, it can easily be replaced using any small, strong magnet. It's possible you may be able to come up with a more secure method of attaching the magnet. For example it should be possible to drill and tap a small hole in the hub and use a screw. There shouldn't be much force on the magnet. Even at 40 mph, the wheel is only rotating at around 11.5 revolutions/second, and by my calculation the centrifugal force trying to pull a 10gm magnet placed about 1" from the hub of the wheel will be about 4oz at that speed. I did not feel any vibration due to wheel imbalance either.

The image on the left shows how I attached the magnet to the wheel. I scraped the paint off the wheel and attached the magnet in place using epoxy putty. By placing the magnet close to the hub you can minimize any effect on wheel balance and the centrifugal force on the magnet is minimized. How long it will stay attached I don't know. However if it does come off, it can easily be replaced using any small, strong magnet. It's possible you may be able to come up with a more secure method of attaching the magnet. For example it should be possible to drill and tap a small hole in the hub and use a screw. There shouldn't be much force on the magnet. Even at 40 mph, the wheel is only rotating at around 11.5 revolutions/second, and by my calculation the centrifugal force trying to pull a 10gm magnet placed about 1" from the hub of the wheel will be about 4oz at that speed. I did not feel any vibration due to wheel imbalance either.

On my scooter it's then possible to attach the pick up transducer directly to the front suspension fork using cable ties as shown, with a gap small enough that the magnet induces sufficient signal for the computer to record each wheel revolution. For my particular wheel and tire, the circumference measured 152cm and that's the value I entered as the calibration setting. The best way to measure the circumference of the tire is to measure the distance traveled in one revolution. Chalk a mark in the tire and the ground, then sit on the scooter and roll forward one revolution and make a second chalk mark on the ground. Then measure the distance between the chalk marks. This is quite accurate. My calibration gave speed and distance results within 1% of those I got by using a GPS system to measure speed and distance. The Schwinn bicycle computer I used has a quirk in that it doesn't seem to like to go much over 50mph. Perhaps it's not designed to as bicycles will never normally get to such a speed. The maximum speed it records is around 51 mph. Go much faster and either the indicated speed decreases or reads zero. On my scooter this isn't a big deal since I don't ride over 50mph. Perhaps other bike computers will read higher speeds. I don't know because I haven't tested any.

Since bicycles may be a little smaller than some scooters and the wiring route may take a few turns, the distance between the transducer on the fork and the readout unit mounted somewhere near the instrument cluster may be more than the length of the supplied wire, so you may have to splice in an extension. You need some "slack" in the wiring to allow for movement of the scooter suspension and steering If you tie the wire to the existing speedometer cable, you should be fine since the speedometer cable is routed in such a way that it's not affected by movement of the front suspension or by the turning of the front wheel from side to side. There are also wireless models if you don't like the thought of running an extra wire from your wheel to your dashboard.

You may have to use some ingenuity in mounting the display, but given some epoxy putty, cable ties, self tapping sheet metal screws and/or stick on velcro, it shouldn't be too hard to figure out a place and method of mounting it so that it can easily be seen while riding.

There are a large number of "bicycle computers" available at prices from $10 to $30 depending on the size and complexity of the display and the number of functions they can measure. There are even units which will measure temperature and altitude! A small section is shown below. Obviously a larger display is easier to read when you are riding.